Lashing and securing straps are essential elements in cargo stowage. These straps are used to secure and hold goods in place during transport, thus preventing possible movement and damage. However, due to the continuous use and conditions to which they are subjected, it is important to regularly check the condition of these straps to ensure their effectiveness and avoid accidents.

Check the fastening straps for damage

Here are some recommendations to check for damage to lashing and lashing straps in stevedoring.

Visually inspect

The first thing you should do is visually inspect the webbing and tie-down straps for damage. Look for signs of wear, cuts, tears or deformities in the fabric, hooks and buckles. Pay particular attention to areas of increased tension and seams.

Check the resistance

To make sure that the straps, as part of the lashing and lashing systems, are in good condition, you should check their strength. This can be done by means of a tensile test. Take a sample of the webbing and apply a gradual force until breakage occurs. If the webbing breaks before reaching 80% of its nominal strength, it should be replaced.

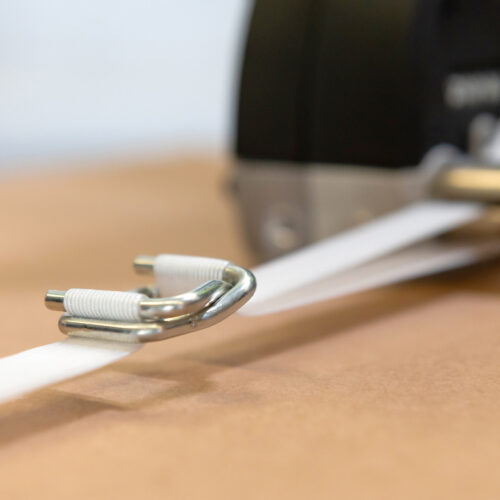

Check the condition of the buckles and hooks.

Buckles and hooks are critical parts of webbing and tie-down straps. Make sure they are in good condition, with no breaks or deformities. Check that the buckles are securely fastened and that the hooks close securely.

Check seams

The seams of the fastening and lashing straps should also be checked. Look for possible tears, loose threads or worn seams. If you find any problems, the webbing needs to be repaired or replaced.

Take into account the regulations

In addition to visual and physical inspections, it is important to be aware of current regulations regarding the use of lashing and tie-down straps. Consult specific regulations to ensure you meet minimum safety requirements.

In J2 Servid we offer the necessary training for your workers to know and stow the goods according to European standards: Stowage courses for cargo and transport cargo and transport professionals.

Train your staff

Ensure that all personnel involved in the stowage and securing of loads are properly trained in the correct use of lashing and lashing straps. This includes the correct positioning of straps, choosing the right tension and the safe handling of hooks and buckles.

Final recommendations for cargo lashing and stowage

In addition to regular checking of lashing and securing straps, there are other important recommendations to be taken into account to ensure safe stowage and to protect goods during transport:

Use the right equipment

Select quality lashing and securing straps that meet the necessary specifications for the type of cargo to be transported. Also use other lashing devices, such as straps or webbing, as needed.

Distributes the load evenly

Make sure the load is evenly distributed in the vehicle or container. Avoid placing heavy objects on top of lighter objects and use separators or blocks to prevent loads from shifting sideways.

Protects goods

Use goods protection materials, such as inflatable bags, rubber anti-skid pads, protective corner protectors or goods protection with padding, to avoid possible damage due to friction or impact during transport. It is also important to protect against adverse weather conditions, with isothermal insulation and desiccant bags for containers. In addition to lashing, it is important to protect the goods adequately.

Follow the manufacturer’s recommendations

Be sure to follow the tie-down manufacturer’s recommendations for installation, maintenance and maximum load capacity. This will help maintain safety and prolong the life of the straps.

Check before each trip

Before each trip, recheck the condition of the belts, as well as the load distribution. Make sure that everything is in order and that there have been no changes in the transport conditions.

Regular checking for damage to lashing straps in stowage is essential to ensure their effectiveness and the safety of the cargo during transport. Remember that proper stowage, securing and lashing of cargo is key to safe and efficient transportation.