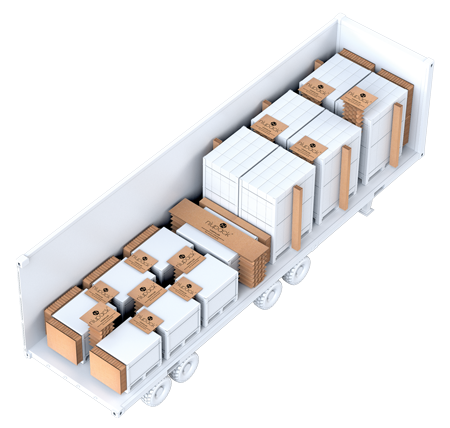

The correct securing of cargo on a truck is essential to ensure the safety of the load, the driver and other road users. Cargo securing systems on the truck play a crucial role in this regard. These systems are designed to prevent the load from shifting during transport, reducing the risk of accidents and damage to the goods.

Types of locking and lashing systems for securing cargo on trucks

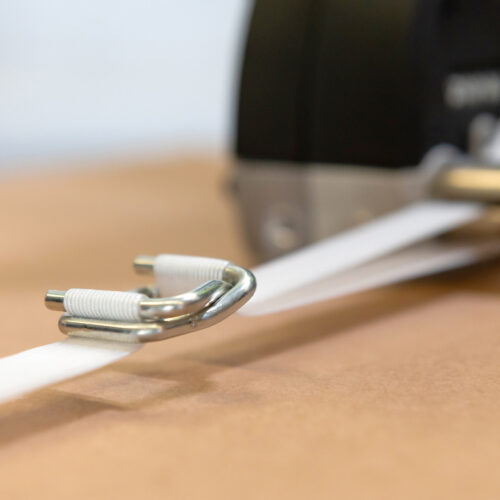

Tensioners and lashing straps

Tensioners and lashing straps are one of the most common lashing systems used to secure cargo on a truck. These devices consist of a heavy-duty polyester webbing that is attached to the load and tensioned by a tensioning mechanism. The ratchets or tensioners allow the tension of the straps to be adjusted to secure the load safely. This system is effective for securing loads of different sizes and shapes, and is versatile and easy to use.

In J2 we have the ProLash system, made of high quality polyester, which in different formats can be adjusted both manually and with the ProLash Tools pneumatic tensioners.

These ProLash lashing and lashing straps are ideal for use on trucks, as they are designed to secure goods efficiently and safely, and can also be used for sea containers.

It is very simple to use:

- Belt selection: ProLash belts are available in different widths (32 mm to 50 mm) and linear strengths up to 7,500 daN and in system up to 10,000 daN, allowing to adapt to various load requirements.

- Load preparation: Make sure that the load is well distributed and positioned on the truck. This is essential for effective securing.

- Anchoring of the tapes: there are different systems for anchoring the tapes to the truck’s fastening points, either with open hooks, closed hooks or by passing the tape directly and fastening it with the buckles. These systems can be used in trucks or containers.

- Tensioning the straps: Once anchored, tension the straps properly to ensure that the load does not move during transport. This is crucial to avoid shifting that could cause accidents.

- Verification: Before starting the trip, check that all straps are securely fastened and that the load is secure. It is advisable to make checks during the trip to ensure that there is no loosening.

- Disassembly: Upon arrival at destination, the belts are unanchored and those that are reusable are stored for future use.

The use of ProLash on trucks not only improves cargo safety, but is also a fast and economical solution.

Blocking and protection with padding

The cargo Void Filler system Niupack consists of adaptable cardboard structures that are strategically placed in the empty spaces between the cargo and the truck walls, creating a physical barrier that prevents cargo movement during transport. Void Filler fits into existing voids, providing effective and secure securing.

It is a system that adapts to the size of the load, filling empty spaces in a customized manner. This ensures optimal securing and prevents the load from shifting during transport.

Keeping cargo immobile and securely fastened, Niupack helps prevent damage to products due to sudden movements or shocks characteristic of truck transport.

The correct securing of cargo on a truck is a fundamental aspect to ensure safety in the transport of goods. Cargo securing locking systems are essential tools to prevent accidents and damage to the goods during transport.

Investing in quality locking systems is a preventive measure to ensure safety and protect transported goods, and it is crucial that truck drivers and operators are trained to use these systems properly and comply with current safety regulations, which is why stowage courses for cargo and transport professionals can be an excellent option to consider.