Shipping is one of the oldest and most popular ways of moving goods over long distances across oceans and seas. With the development of maritime technology and infrastructure, this mode of transportation has become central to international trade and the global economy.

Let’s take a look at the advantages and disadvantages of maritime transport, which is considered an efficient and economical option for moving large volumes of goods globally.

Advantages of maritime transport

Load capacity

One of the main advantages of maritime transport is its ability to carry large volumes of goods. Cargo ships can carry tons of goods at a time, making it an ideal option for moving large quantities or larger, heavier goods.

Cost effective

Compared to other forms of transport such as air transport, maritime transport is generally more economical. This is because the operating costs of ships are lower in terms of fuel and maintenance, which translates into more affordable shipping rates for exporters and importers.

Global connectivity

Maritime transport connects different regions of the world, facilitating international trade and the export and import of products on a global scale. Seaports act as key logistics hubs that interconnect the supply chains of different countries and continents.

Security

Despite the challenges and risks involved in navigation on the high seas, maritime transportation has international regulations and safety measures that ensure the protection of the crew, cargo and the environment itself. In addition, technological advances in navigation and communication systems have improved safety in the maritime industry.

Disadvantages of maritime transport

Speed

Although maritime transport is efficient for moving large volumes of goods, its main disadvantage lies in speed. Cargo ships tend to be slower than other modes of transport such as air transport, or land transport over medium distances, which can result in longer delivery times, especially for perishable or urgent goods.

Dependence on weather conditions

Maritime navigation is subject to weather and oceanographic conditions, which can cause delays in vessel departure and arrival times. Storms, strong winds and storm surges can affect the safety and efficiency of ocean voyages, causing disruptions in supply chains.

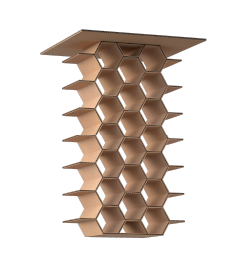

In addition, this can affect the goods, so in J2 we have a series of products designed to protect goods against adverse conditions. Some products require specific environmental conditions for their conservation, which is why J2’s isothermal cover for thermal protection will save us the transport in a specific container for the transport of these products. The ProTerm range is created to thermally insulate the container or surface inside it.

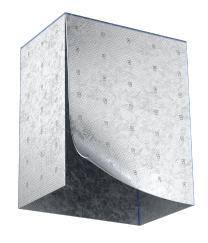

Moisture inside shipping containers is one of the main problems and cause of complaints in maritime transport, as it can cause fungus, mold, corrosion or rust in the goods. Container desiccant bags are a practical solution, as they absorb moisture and make it easier for the goods to reach their destination in perfect condition.

Customs formalities and port logistics

Maritime transport involves the coordination of multiple actors and logistical processes, from the loading and unloading of goods to customs formalities and documentation management. Delays at ports, maritime traffic congestion and bureaucratic procedures can generate additional costs and operational difficulties for companies.

While it presents significant advantages in terms of carrying capacity, cost and sustainability, it also faces challenges, many of which can be addressed with additional products and services.

It is important to strike a balance between taking advantage of the benefits of maritime transport and addressing its disadvantages by implementing innovative measures and practices that promote efficiency, safety and sustainability in this mode of freight transport.