The transport of dangerous goods is an activity that involves special risks due to the nature of the materials involved. It is crucial that strict rules and regulations are followed to ensure the safety of workers, the general public and the environment.

What is defined as dangerous goods

Dangerous goods are those materials that, due to their intrinsic properties, represent a risk to health, safety or the environment during transportation. These goods can be solid, liquid or gaseous and are divided into different classes according to their hazardous characteristics, such as explosive, flammable, toxic, corrosive or radioactive.

Dangerous goods cover a wide range of products, ranging from industrial chemicals to biological substances or radioactive materials. Common examples of dangerous goods include flammable products such as gasoline, toxic substances such as industrial chemicals, corrosive materials such as acids and bases, and explosives such as fireworks.

What regulates the transport of dangerous goods in Spain?

In Spain, the transport of dangerous goods is regulated by Royal Decree 97/2014, concerning the transport operations of dangerous goods by road in Spanish territory. This Royal Decree incorporates international regulations on the transport of dangerous goods, in particular the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR).

Royal Decree 97/2014 establishes specific requirements for the classification, packaging, labeling, documentation and transport of dangerous goods. It also regulates the responsibilities of the different actors involved in transport, such as shippers, carriers and consignees. In addition, it establishes safety measures to prevent accidents and minimize impacts in case of emergency.

How to stow and transport dangerous goods safely and efficiently

To stow and transport dangerous goods safely and efficiently, it is essential to follow certain precautions and good practices. Listed below are some key tips for the safe stowage and handling of dangerous goods:

Classification. It is essential to correctly classify dangerous goods in accordance with current regulations to ensure safe and proper handling.

Packaging. Dangerous goods must be packed in suitable packaging that complies with safety regulations and is resistant to the specific risks of the hazardous substances.

Labeling and signage. It is essential to clearly label dangerous goods containers with appropriate pictograms and warning signs to inform workers and emergency services of the associated risks.

Complete documentation. Appropriate documentation, such as the Material Safety Data Sheet (MSDS) and the transport certificate, is required to inform about the characteristics of the dangerous goods and the necessary precautions.

Staff training. It is essential to train personnel involved in the handling and transport of dangerous goods so that they are familiar with the risks and know how to act in case of emergency.

Follow-up and control. Monitoring and control mechanisms must be established throughout the transportation process to ensure compliance with regulations and prevent incidents.

Tygard

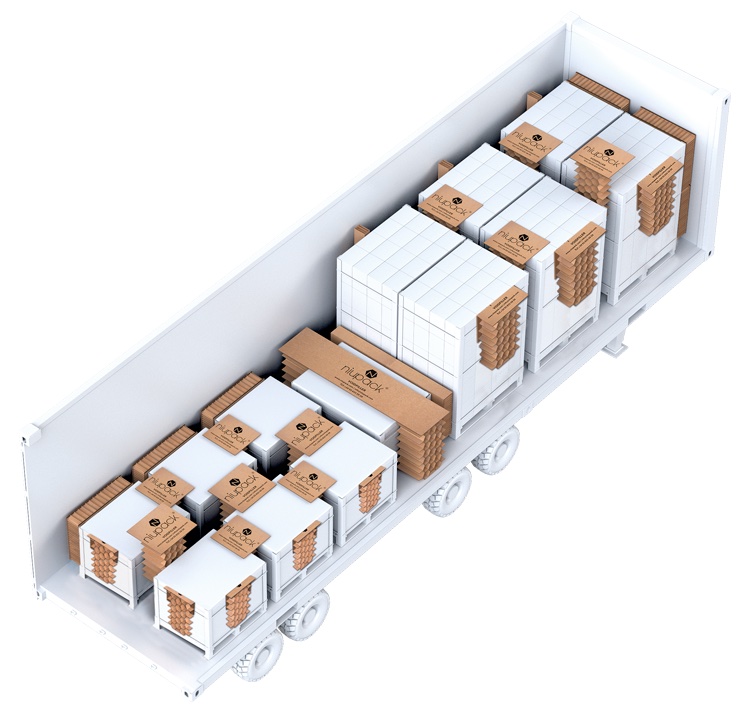

At J2 we have the most versatile dangerous goods protection system on the market, Tygard. This system is manufactured with a 40 cm wide flexible band, formed by more than 7800 high resistance multifilaments. It is laminated with a high-strength acrylic adhesive that adheres to the container walls for maximum strength, but removes easily upon arrival at destination without leaving a trace on the container walls.

It can be used with drums, Big-Bags, IBC’s, dangerous goods, explosives and all types of palletized goods, and complies with the cargo securing standards established by the IMDG Code or International Maritime Dangerous Goods Code, the Federal Motor Carrier Safety Administration (FMCSA), the United States Coast Guard (USCG) and the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR).

Conclusion

The transport of dangerous goods is an activity that requires a careful and responsible approach to ensure the safety of people and the environment. It is crucial that the established regulations are followed and that adequate prevention measures are adopted to minimize the risks associated with this type of goods.

Through safe and efficient stowage and handling, the transport of dangerous goods can be carried out effectively and without compromising safety.

More information:

- Definition and types of dangerous goods in the DGT web site.

- Royal Decree 97/2014, of February 14, regulating the transport operations of dangerous goods by road in Spanish territory.

- European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR 2023)