The transport of goods via sea containers is a fundamental part of the international and global logistics chain. However, to ensure the integrity of products during their journey, it is essential to consider container insulation.

Do shipping containers need insulation?

Shipping containers are known for their robustness and strength, as they are made with steel walls that protect goods from adverse conditions during transport. However, these same characteristics can cause containers to overheat in the summer and cool in the winter. This can cause damage to some temperature-sensitive products, such as food, chemicals or pharmaceuticals.

In addition, during their sea voyage, containers are exposed to extreme climatic conditions, such as humidity, water salinity and temperature variations. These factors can affect the quality of the products stored in the container if an adequate insulation system is not in place.

In this sense, the insulation of sea containers becomes essential to maintain the temperature and humidity within the appropriate limits, thus protecting the goods and ensuring their integrity during transport.

Benefits of insulating sea containers

Insulating sea containers has a number of benefits for both the products being transported and the logistics companies. Some of the key reasons why it is important to insulate containers are as follows:

Protection of merchandise. Thermal insulation protects temperature-sensitive products from sudden changes that could deteriorate their quality. By maintaining a constant temperature inside the container, it ensures that the goods arrive in optimum condition at their final destination.

Compliance with regulations. In certain sectors, such as the pharmaceutical or food industry, there are strict regulations on the transport of products that require specific temperature conditions. Insulating containers ensures compliance with these regulations and avoids possible penalties or losses due to non-compliance.

Cost reduction. Adequate insulation can contribute to reducing operating costs for companies, since it minimizes losses due to merchandise deterioration and avoids customer complaints due to products damaged during transport.

Reputation enhancement. Ensuring the quality and integrity of transported goods helps build an image of trust and professionalism with customers and business partners. A reliable and secure transport service can generate positive recommendations and customer loyalty.

What is isothermal insulation?

Isothermal insulation involves the installation of specialized materials in the walls, roof and floor of sea containers in order to control heat transfer and maintain a stable interior temperature. These materials offer thermal insulation properties that prevent heat loss in winter and overheating in summer.

Isothermal insulation also helps to regulate humidity inside the container, preventing condensation and mold formation, which could damage the stored goods. In addition, this type of insulation can be complemented with refrigeration or heating systems to maintain specific temperature conditions according to the needs of the transported products.

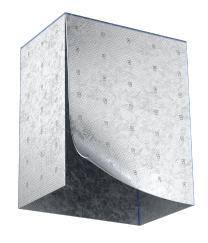

In J2 Servid we have isothermal cover for thermal protection, our ProTerm Container model, specially designed for 20′ and 40′ containers. We also have the ProTerm Palet pallet covers, ideal to avoid sudden temperature changes during your shipments in groupage or air transport, available in different formats and with the possibility of custom manufacturing. More info here or contact us.

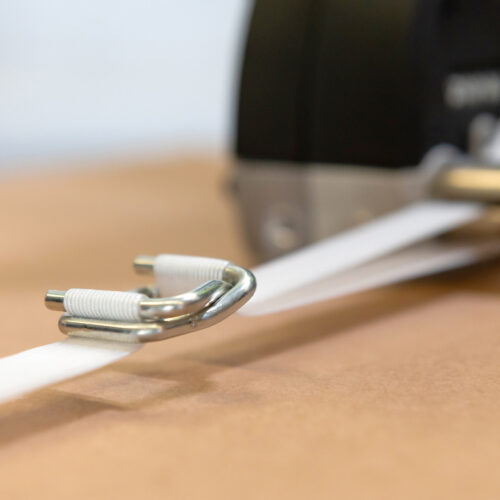

We also have a temperature, humidity and location recording system, ProControl, which is ideal for use in sea container shipments. We can monitor and review temperature and humidity changes during transport with ProControl Temperature, a temperature data logger, and ProControl Humidity + T, a temperature and humidity data logger. And if we are looking for something more complete, with ProControl Track, it provides data and reports on temperature, humidity, light and location.

As we can see, the insulation of freight containers is an indispensable measure to ensure the quality, safety and integrity of products during their journey. The use of specialized materials and the implementation of good practices in handling and monitoring temperature and humidity are key to ensure efficient transportation and protect the supply chain.