Safety on the road and during transport

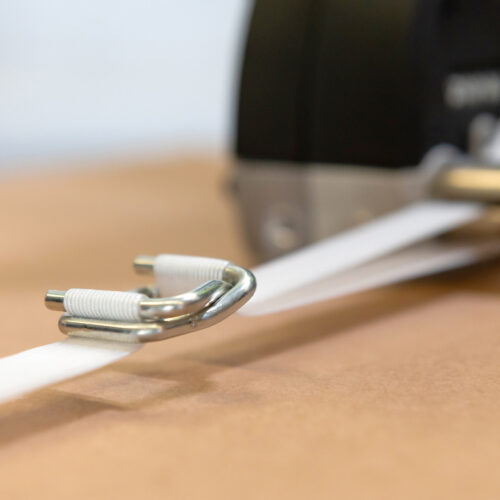

A cargo securing system in poor condition or incorrectly installed can cause accidents on the road. An improperly secured load can shift during the journey, causing dangerous situations for both the vehicle driver and other road users. It is therefore crucial to periodically check load securing systems to ensure that they comply with established safety regulations and that they are in optimal working condition. Regular inspections make it possible to detect possible faults or wear on securing elements such as straps, chains or lashings and to take corrective measures in good time. In this way, accidents are prevented and safe and efficient transport of cargo is ensured. In the post How to check for damage to lashing and lashing straps in stevedoring we have given some tips on this subject.Regulatory compliance

The transport regulatory authorities establish specific regulations regarding the securing of cargo, with the aim of ensuring safety on the roads. These regulations cover aspects such as the load capacity of vehicles, the types of lashing permitted and the correct distribution of the load inside the transport.

Periodic inspection of cargo securing systems is essential to ensure compliance with current regulations on the transport of goods. This avoids penalties and fines for non-compliance with regulations, as well as, as we said, avoiding possible accidents resulting from inadequate load securing.

We recommend the articles Las obligaciones en el amarreamiento de cargas, ¿Quién es el responsable de la carga y la estibacion en camión? and Las mejores prácticas en la sujeción de cargas y qué hay que tener que tener en cuenta, where we go into more detail on this subject.

Cost savings

Keeping load securing systems in good condition is not only important from a safety and regulatory compliance standpoint, but also represents a long-term cost savings for the company. Proper maintenance of these systems helps to prolong their service life and prevent premature deterioration, reducing the need for frequent replacement.

Therefore, it is advisable to establish a regular inspection plan for these systems, in order to guarantee their correct operation and minimize risks in cargo transportation. At J2 we have certified lashing systems, manufactured with high quality polyester, approved and certified by several international laboratories, and available in various widths and strengths. If you want to know more, please contact us.