Void filler, the definitive ECOLOGICAL solution to avoid the domino effect

THE DEFINITIVE AND ECOLOGICAL SOLUTION TO THE DOMINO EFFECT

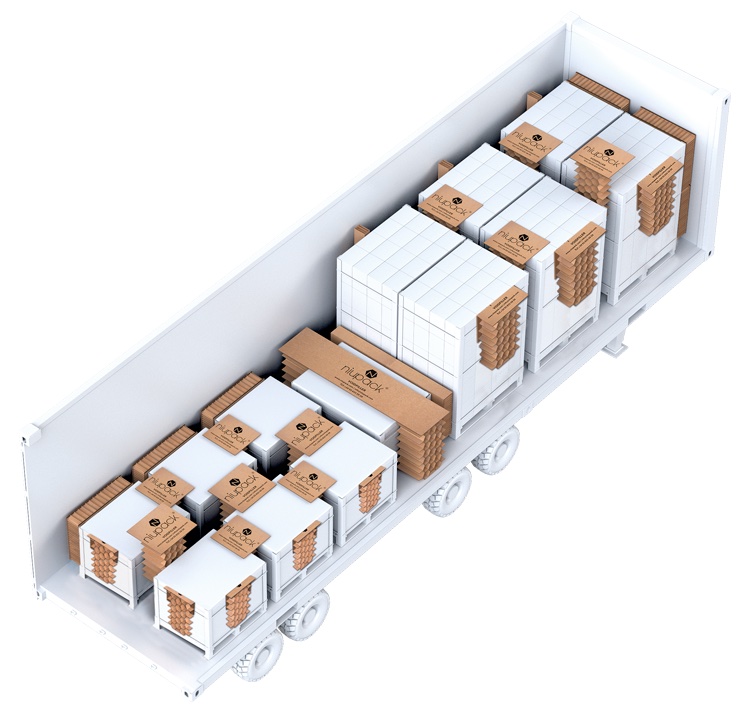

The new and revolutionary void filler to fill the gaps between pallets and prevent the movement of merchandise during transport.

What benefits does Niupack have?

- Unique system in the market.

- Avoid the domino effect that can occur due to braking or acceleration during transport.

- Sustainable and recyclable model, certified by FSC and PEFC.

- Possibility of custom manufacturing.

- Effective and easy to use system.

- Economical, reusable and foldable solution.

Avoid cargo movement during transport

The ecological solution of J2 Servid

It is an ECOLOGICAL system (available with FSC and PEFC certificate), reusable, foldable and recyclable.

Ideal system for road transport

Honeycomb

Made of cardboard and in the shape of a honeycomb, this innovative cargo void filler system is placed to fill the gaps between the pallets, as a separator, thus avoiding the movement of pallets during transport.

Custom manufacturing

Economic and effective solution

Niupack Categories

Discover the void filler that best suits your load

Niupack Top

Niupack Top

The smallest model in the family to avoid the domino effect that can occur as a result of driving.

Niupack Large

Niupack Large

Aimed at large consumption sectors such as food and beverages and laboratories, the chemical industry and transport and logistics companies in general.

Niupack Side

Niupack Side

This voidfiller has a smaller, foldable upper side cover so that it can be placed inside the stretch film that wraps the pallets, avoiding placing the cover on top of the pallet and reducing cardboard.

Niupack Double

Niupack Double

Union of two cargo void filler systems. Ideal to protect loose pallets in trucks and to gain longitudinal space in maritime containers.

Niupack Box

Niupack Box

The voidfiller that can be folded for transport or storage, thus saving a lot of space during transport and storage.

Niupack Block

Niupack Block

Used for rigid goods in the sectors of machinery, consumer electronics and transport and logistics companies in general.

Niupack Panel

Niupack Panel

The honeycomb system is covered by two panels of kraft paper. It is ideal for protecting the sides of the pallet and for separating and stabilizing stacked pallets.

FAQs Niupack

The cargo protection system with padding consists of the use of materials to fill the gaps between the pallets. This is done to protect the merchandise during transport. This measure is especially necessary to prevent damage during movement and storage.

The filling of gaps between pallets helps to reduce the movement of merchandise during transport. This is done by using materials such as cardboard, foam, plastic pellets, bubble wrap, among others. These materials are placed between the pallets and adjusted to fill the gaps between them. This makes it possible to stabilize the contents and reduce the risk of the goods shifting during transport. This is especially important for fragile or high-value goods and ensures that no pressure is put on the goods and no vibration damage occurs. This is especially important for bulky or heavy goods that need adequate support for storage.

Our Niupack system is ideal for cargo protection.

The plastic degradation process is between 100 and 1000 years, while cardboard takes at most 1 year to degrade. Finding more sustainable, recyclable or reusable solutions to replace plastic, is one of the main objectives in the packaging market and the industry in general. That is why at J2 Servid we have launched the sustainable, reusable and recyclable Niupack.

It is a simple and practical system for the protection of goods to prevent the movement of the load during transport and avoid the domino effect.

Niupack is a 100% ecological, sustainable and environmentally friendly product. It is made from recycled material and is also recyclable, reusable and foldable, which means that as well as from saving space, it is a product with a very low environmental impact.

The Niupack is a product for goods protection made of cardboard, affordable, quick to install (without additional tools), resistant, foldable, ecological and easy to use.

Niupack is a product that can be tailor-made, and to choose the correct thickness, it has to be 2 or 3 centimeters less than the space we have between pallets. If, for example, the space between the pallets is 15 centimeters, the ideal thickness of the Niupack would be 12-13 centimeters. If you have any question, at J2 Servid we will tell you the best measure to protect the goods.

J2 Servid has different patented models, both nationally and internationally.

Usually, the Niupack Top or Niupack Side models are used for truck loads and specifically for the food, beverage and non-food sector. The other models are more focused on other types of cargo, for sea containers or trains.

For example, the Niupack Large model is specially designed for sea containers, the Niupack Box for lorries, containers and trains, and the Niupack Double model for lorries and containers, to be able to apply the correct weight distribution between the axles.

If you have any question, J2 Servid will indicate the best model to protect the goods.

As it is a made-to-measure product, it can cover any space. However, it is not recommended for spaces larger than 65 centimeters.

No, it is a completely manual product, easy and quick to install, in about five seconds and without to use any tool.

Niupack can be personalized from minimum quantities. It can be personalized with your logo and 1-2 inks at a small additional cost.

It can be used for any kind of transport, but the most common are trucks, sea containers and railway wagons.

There are different models listed in the AAR (Association of American Railroads) guide, so it is considered a type of packaging suitable for the goods protection in rail transport.

The tests that we carried out with the Niupack models are a resistance tests. These tests consist of apply a continuous force during a determined time, simulating the forces that it would receive during the transport of goods. In this way it is possible to study the resistance depending on the model or structure.

At J2 Servid we have a quality department with the most advanced technology and machinery, to study the resistance of Niupack. One of these machines is a compressometer, to see what the Niupack compressive strength is when it is exposed to a continuous force, as it could be during transport. With this valuable information, we can confirm that most Niupack models resist between 1,300 and 3,000 kilograms, although other models can be manufactured with even higher strength if required.